Student Leads Boy Scout Team in 3D Printing Medical Equipment for Underserved Communities

|

Article Written By: Jen Wilson Director of Manufacturing & Design, Glia |

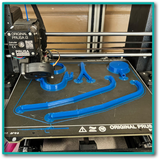

Alex Rokko, a student from New Jersey, lead a team of Boys Scouts in utilizing 3D printing technology to create medical equipment for under-served communities as his Scout Eagle Project for Troop 331.

Alex Rokko, a student from New Jersey, lead a team of Boys Scouts in utilizing 3D printing technology to create medical equipment for under-served communities as his Scout Eagle Project for Troop 331.

With the help of Glia, Rutgers U. MakerSpace, and Bell Works, he lead the team in assembling and distributing Glia’s open source, medical grade stethoscopes for first responder relief efforts in distressed areas.

Alex worked to produce the components for stethoscopes which scouts would assemble for war relief efforts and other emergency service providers overseas. He then reached out to Glia with donated funds to purchase our 3D printed stethoscopes for distribution to these places. Glia helped in the assembly of the devices, and with other 3D printing information and advice.

On June 10, 2023, Alex led a team of 20+ Scouts and community members in assembling and packaging the stethoscopes for distribution. The event took place at Bell Works, the historic home of AT&T’s Bell Labs instrumental in research over the past century. The stethoscopes were distributed through Doctors without Borders, while others went to Ukraine.

On June 10, 2023, Alex led a team of 20+ Scouts and community members in assembling and packaging the stethoscopes for distribution. The event took place at Bell Works, the historic home of AT&T’s Bell Labs instrumental in research over the past century. The stethoscopes were distributed through Doctors without Borders, while others went to Ukraine.

Alex’s goals for this project were to:

-

Create an online learning platform to enable Boy Scouts to create 3d printed stethoscopes

-

Raise funds for the production of medical equipment and associated costs

-

Assemble and distribute items to support Ukrainian war relief efforts and other emergency service provider

-

Promote scouting as a positive solution to societal needs by applying technology and raising awareness

-

Enable scouts to continue efforts towards application of 3d printed manufacturing towards societal development

To quote Alex,

“Glia has been a phenomenal help in achieving these goals. The Glia team has helped me in every stage of the project beginning with research and design of medical equipment that could be produced affordably at scale all the way to prototype design and production. Glia helped coordinate efforts with Rutgers University to produce additional equipment and helped supply design, components supplies and guidance through every step of the project to the team of students and staff at Rutgers Makerspace which helped expand the scope of my project exceeding initial expectations. Carrie Wakem and Jen Wilson in particular were incredibly helpful in working through the design and production details. They were instrumental in supporting my efforts and producing medical grade components in time and meeting standards required for our needs.”

Alex was very thankful for our guidance through this process, and he also gives a special thanks to Rutgers University and its Rutgers Makerspace, and Dr. Stephanie Reynolds for their tremendous contributions and support to Alex's project. Thanks also to Monmouth Council, Scouts of America, for their guidance; to Rutgers Enable and the Enable Organization for their advice on 3D Printing Technology; and to Bell Works for supporting the assembly event.

Alex was very thankful for our guidance through this process, and he also gives a special thanks to Rutgers University and its Rutgers Makerspace, and Dr. Stephanie Reynolds for their tremendous contributions and support to Alex's project. Thanks also to Monmouth Council, Scouts of America, for their guidance; to Rutgers Enable and the Enable Organization for their advice on 3D Printing Technology; and to Bell Works for supporting the assembly event.

--------------------------------

Join our mailing list by entering your email address below and stay up to date on our projects, receive information on new devices, projects, releases, and of course to ensure you never miss a release of our newsletter, The Open Source.